Am Donnerstag (15. Juli 2021) wurde ein Verdampfer mit interessanter Geschichte als technisches Exponat vor dem VTA-Büro- und Betriebsgebäude in Niederwinkling (Deutschland) aufgestellt. Mit einer Höhe von fast 12 Metern und einem Gewicht von ca. 30 Tonnen ist der Apparat einer der größten jemals hergestellten Kurzwegverdampfer und war auch eines der ersten Projekte von VTA.

Historischer Hintergrund

Bereits kurz nach der Gründung im Jahr 1994 wurde VTA mit der verfahrenstechnischen Planung sowie der Lieferung der Hauptkomponenten einer Kurzweg-Destillationsanlage zur thermischen Entsäuerung von Palmöl beauftragt. Der Endkunde war ein Produktionsbetrieb auf der indonesischen Hauptinsel Java. Die Aufgabe bestand darin, rotes Palmöl herzustellen: Die Schwierigkeit bestand darin, die freien Fettsäuren aus dem Palmöl abzutrennen, ohne das Karotin abzutrennen, das dem Palmöl seine rote Farbe verleiht.

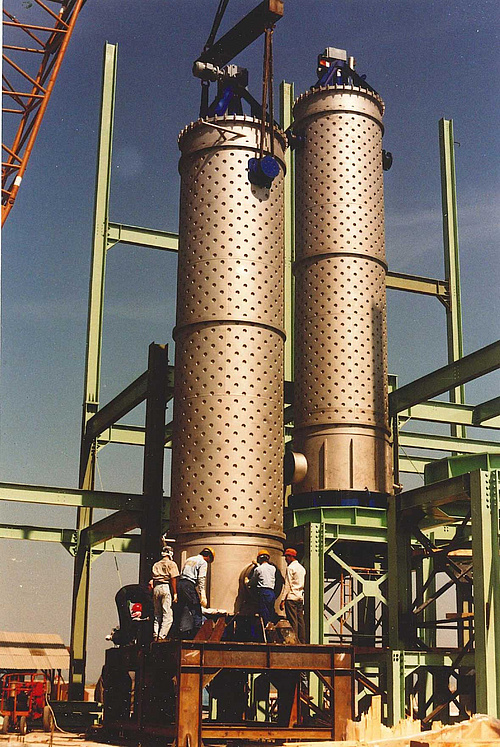

Die Hauptkomponenten waren zwei Kurzwegverdampfer (Typ VK 2000-5000) mit einer Fläche von 50 m² und einer beheizten Länge von 8 m. Das Besondere an diesem Projekt war, dass bisher kein Verdampfer dieser Größe hergestellt wurde. Die Hochdruckdampfbeheizung mit 35 bar Sattdampf war für die damaligen Ingenieure eine große Herausforderung, da für einen Innendurchmesser von 2 m eine spezielle Heizmantelkonstruktion erforderlich ist. In enger Zusammenarbeit mit der Schwesterfirma STREICHER Maschinenbau in Deggenau (Deggendorf) wurde die Herausforderung angenommen und das Projekt erfolgreich umgesetzt.

Die Verdampfer und andere Komponenten wurden 1997 in Indonesien zusammengebaut, aber aufgrund der politischen Situation im Land konnte die Anlage erst 1999 in Betrieb genommen werden. Seitdem produzierte die Anlage bis 2005 entsäuertes Palmöl.

Im Jahr 2007 wurden die Hauptkomponenten der Anlage von VTA zurückgekauft und nach Deutschland verschifft. Nach der Ankunft in Niederwinkling wurden die beiden Verdampfer eingelagert und wieder zum Verkauf angeboten. Ein Gerät wurde als Teil einer kompletten Industrieanlage an ein Unternehmen in Zentralfrankreich geliefert und in Betrieb genommen, wo es zur Herstellung von Biodiesel eingesetzt wird. Der zweite Verdampfer war seit seiner Ankunft im Jahr 2007 ohne weitere Verwendung vor Ort gelagert worden.

Der Apparat ist vor dem Büro- und Fabrikgebäude von VTA aufgestellt

Aufgrund der historischen Bedeutung des Geräts wurde beschlossen, das technische Meisterwerk als Denkmal vor dem Büro- und Betriebsgebäude von VTA in Niederwinkling (Deutschland) aufzustellen. Der Apparat wurde auf eine Stahlkonstruktion montiert, um ihn von unten zugänglich zu machen. Außerdem wird er mit einer Beleuchtung ausgestattet, um das Innenleben des Verdampfers zu untersuchen und die Funktionsweise zu verstehen.

Oliver Stoll (Geschäftsführer, VTA GmbH & Co. KG) und Bernhard Senninger (Technischer Leiter, VTA GmbH & Co. KG) waren zusammen mit Ludwig Waas (Bürgermeister von Niederwinkling) und der lokalen Presse vor Ort, um die Installation und Montage zu begleiten.

Oliver Stoll ist stolz, das Einzelstück hier am VTA-Hauptsitz zu präsentieren:

"Der Verdampfer ist eine technische Meisterleistung. Es ist etwas ganz Besonderes, ihn hier aufzustellen. Für unsere Mitarbeiter und Kunden aus aller Welt ist der Verdampfer eine Demonstration der Technik, Erfahrung und Qualität, die wir nun schon seit mehr als zwei Jahrzehnten liefern."

Link zum Video "Kurzwegverdampfer wird als Denkmal bei VTA aufgestellt"