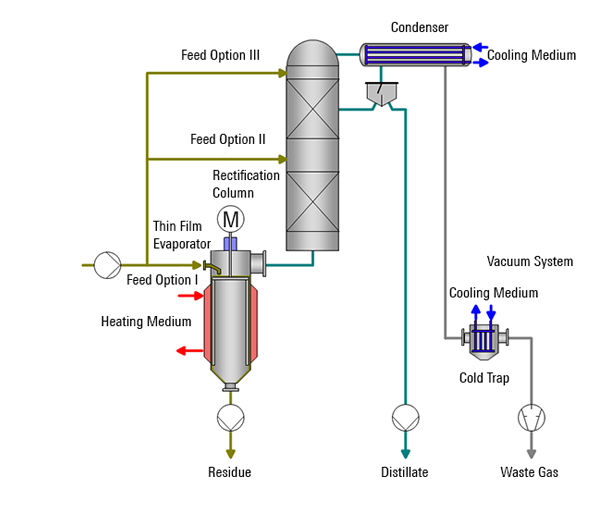

Heat sensitive products having closer boiling points of the lighter and the heavier fraction are difficult to be separated in single stage systems. Combining packed fractional distillation columns with thin film or wiped film evaporators as reboilers improve the separation of such products. The larger number of theroetical stages in the fractional distillation column allows good product yields and purities. The low residence time in the reboiler as well as the low operating pressures avoid thermal degradation of valuable products. The purification of flavor and fragrances, special nutitional products, Omega-3-fatty acids, heat instable fine chemicals or pharmaceuticals are some application examples for this process solution.

Are you interested this process solution?

Testing at VTA test center?

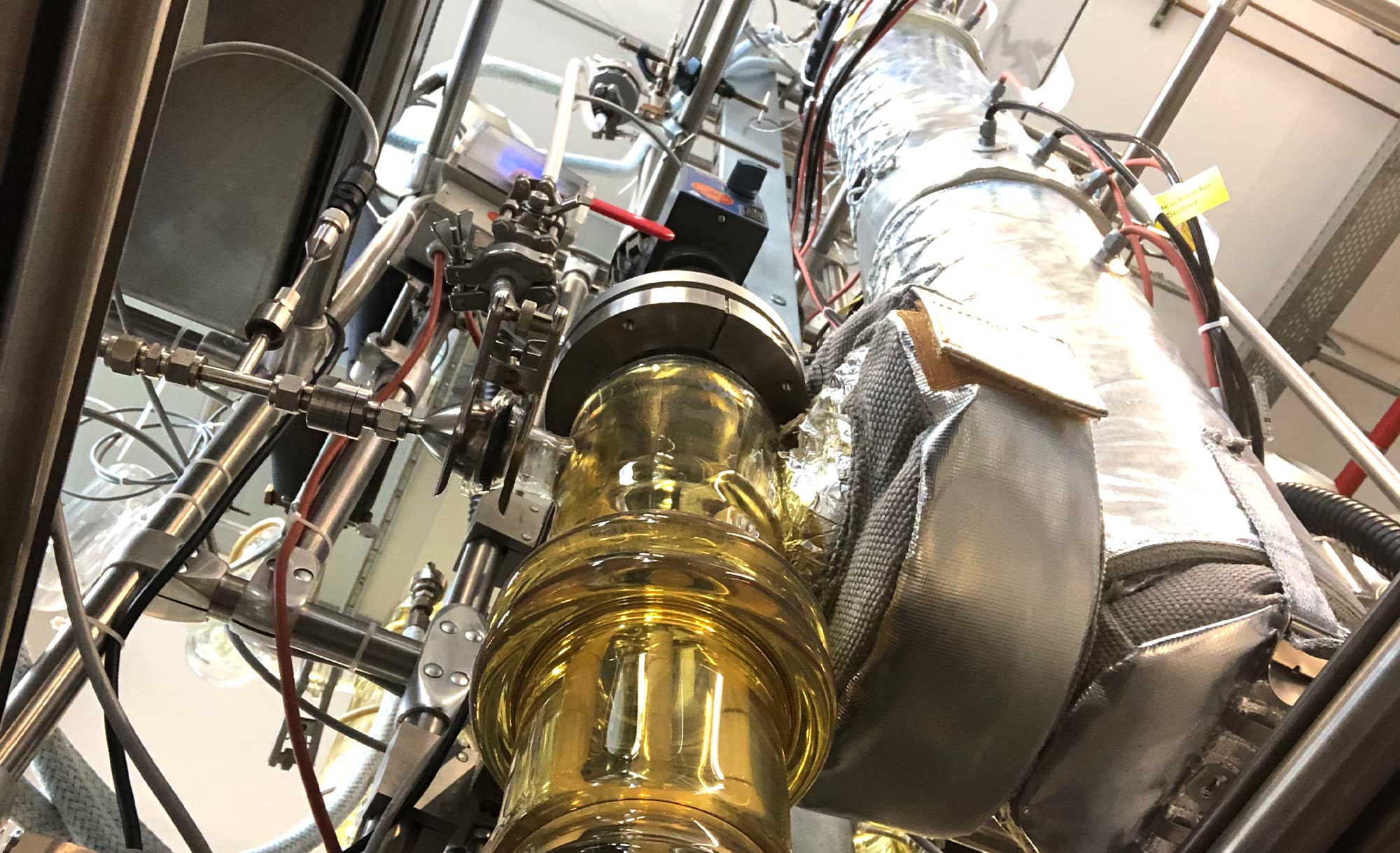

VTA delivers package units in laboratory, pilot and industrial scale. Package units are skid mounted, pre-assembled systems for wiped film

and short path distillation, rectification and thin film drying.

All core components, like evaporators, condensers, vessels and piping, are manufactured in modern manufacturing facilities by highly qualified

workers either by VTA or within the STREICHER group.

All engineering services are performed entirely inhouse at VTA. By minimizing the interfaces, a smooth project execution is ensured.